National Chopper Club

Our machines

To be a member of the NCC you must own a custom motorcycle or trike

Here are some of our machines

National Chopper Club

Our machines

To be a member of the National Chopper Club

you must own a custom motorcycle or trike

Here are some of our machines

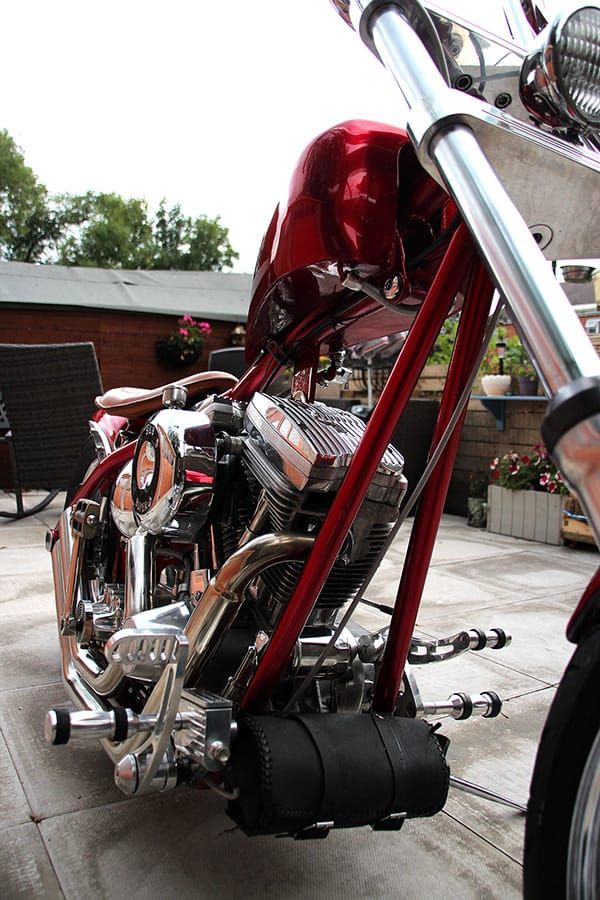

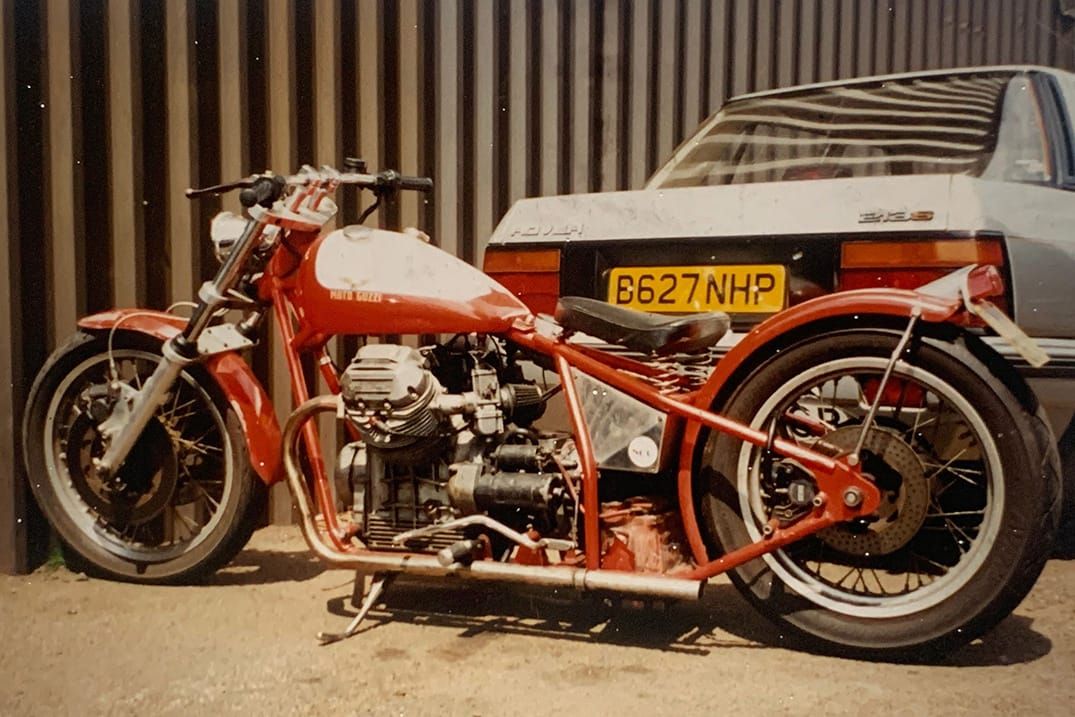

Houdi - National Chopper Club President

Big Red

I bought the engine back in 1998; it was already gas flowed with a big cam, polished rocker arms and a few other bits done to it. It sat in the shed as I saved for a frame which took me around 12 months before I could order a rigid frame from Cobra Engineering down in Gosport.

The headstock was raised by 5 inches and a 36-degree rake produced the classic, Old-School lines that I had always wanted in a chop. I wanted to mix the traditional look of steel rim wire wheels with the new (at the time) look of the 200-back tyre. I managed to buy a stainless-steel offset 8” rim and mated it to a bog-standard Harley Softail Hub.

The raised headstock and rake meant that a set of 8” overs was required mated with a 5 x 16 Harley front wheel. To get the look I wanted I ended up having the chunky slab yokes made with 12” centres between the forks. I cut and welded a rear guard from Motorcycle Storehouse that was nice and short to show off the fat tyre but I wanted a step to it rather than a full curve, it is quite unusual but I like it. This was then mounted with some clever hidden fixings on machined aluminium struts, I had some essential help with all this from Rich and Sam (Mercia NCC) Performance machine calipers were used front and rear.

The bike ran like this for 15 years or so with gradual development and changes along the way such as a Primo Belt primary drive in the original case, a retch gearbox, hydraulic clutch conversion as well as several different carb, exhaust, Fuel Tank, oil Tank, Handlebar and Paintwork options. Through all of this I always found myself rushing to get the bike back on the road following all of these changes and often had to compromise on quality of finish or the parts I used as a result. Steve Whitmore (formerly NCC Leics) was hugely helpful with one particular makeover, making some nice new high level stainless pipes for me and mounting the new oil tank and seat.

Despite me making every effort to avoid the ‘Billet Barge’ look I am a sucker for good chrome, the chrome on this bike has always been taken care of by Honest Kern in Warwickshire.

I finally started a complete Rebuild over the winter of 2019 and then as lockdown hit, I decided to use this enforced hiatus from my busy Club life to make this a rebuild without all the usual compromises.

The bike is now the bike I have always wanted, I will never sell it so I have pleased myself and myself alone. I don’t have to justify what I have spent on against its value as it’s my main bike and I can’t think of anything else more important to spend my money on. I sold my second Hardtail Harley and sunk every penny into this rebuild. It is essentially the same bike but with a real uplift in quality. It now features a fully rebuilt engine with a fantastic standard of cosmetic finish by Maff down at Expressive Motorcycles. Not one fastener was re-used. Maff machined off the lower cooling fins and polished the barrels for the ‘stroker’ look. S&S lifters and blocks were added with a sifton oil pump, new cam, new bore and pistons and in all around £1,100 was spent on engine components, it is now a 37-year-old engine in ‘better than new’ condition.

This ‘no compromise’ approach followed through to the transmission, this was always a weak point of this bike as I tend to ride it quite hard, and so the whole lot was replaced. For me a pretty chop is no use unless you can hammer across the Country at high speed, the bike kicks the shit out of you as you do it but that’s what it’s all about for me, if I wanted a smooth and comfortable ride then I wouldn’t be in the Chopper Club! A Baker 6 in a 4 gearbox was purchased and modified to include the later style ‘splined’ output shaft. A BDL 3-inch belt drive had to be specially ordered as they are not usually supplied without the starter motor ring. This bike has never featured electric start in all the years I have had it, I don’t like electric starters on choppers like this, they are for bikes that are Chopper replica’s, this is the real thing! Real Choppers are hard work but that’s why riding them long distances is such an achievement.

By now I had already fitted the 21” Harley front wheel and lowered the forks slightly to compensate by adding a spacer to the damper rods, a great idea I got from Eggy (Mercia NCC) Another Fuel tank was purchased from eBay and was attacked with a hole saw to allow it to drop over the frame to give the correct line, this was then welded up by Marcin (NCC Leics) The Ultima sprung saddle was beautifully re-covered in quality leather by Steve Hulm up in Mansfield.

I finally took the plunge and fabricated my own stainless steel Exhaust system. It’s my first one but I have to say I am pretty pleased with it.

I also painted the bike myself using candy red lacquer over coarse metalic silver basecoat with a little silver flake thrown in for good measure. I wanted a single colour this time as I didn’t want anything to detract from the lines of this bike. My spraying technique involves throwing as much paint at it as I can get away with so apologies to Marcin, whose lawn and fence were pink for a few weeks after he offered his shed as a spray booth!

I have tried to do Maff’s superb engine work justice by continuing with all new fasteners throughout and resisted the temptation to re-use old crap as I have put this bike back together. I am pretty chuffed with the end result. It is very much the same bike that has carried me to Club Runs all over Europe for close to 20 years but with a new lease of life. This bike means an awful lot to me, nobody has ever ridden this bike except me, it’s a simple, old-school Chopper with absolutely no frills and I look forward to the two of us hammering around Europe for many more years to come.

Big Red, rigid kicker 84’ 1340 gas flowed motor with S&S Lifters and Blocks were added with a Sifton oil pump, new cam, new bore and pistons with BDL 3-inch belt drive, modified Baker 6 in a 4 gearbox. Stainless steel exhaust system fabricated by Houdi. Rigid frame from Cobra Engineering, headstock raised by 5 inches and a 36-degree rake. 21” Harley front wheel, 200 rear tyre on a stainless-steel offset 8” rim, mated to a standard Harley Softail Hub, Performance Machine calipers front and rear. Paint is candy red lacquer over coarse metallic silver basecoat with a little silver flake by Houdi.

Dan NCC Nottinghamshire

Karma Violet

-

1996 Harley Davidson 1340 Evo Engine and Harley 5-speed gear box. Both rebuilt and re-finished by myself at Rebellion Paintworks in Gloss black and Satin black. Engine Cylinders were stripped and then powder coated by LSN Coatings in Castleford.

-

Primo Brute IV 3” Open primary and dry clutch system. Fully belt driven to final drive and rear sprocket - made to work by Ralfy Customs.

-

Kuryakyn Pro-R Hypercharger and Re-jetted CV Keihin Carb.

-

Custom made sprung saddle made and covered by myself at Rebellion Paintworks.

-

Custom Made Exhaust system built by myself and Ralfy at Ralfy customs.

-

Hand-made full custom built frame by Ralfy at Ralfy Customs and painted by myself at Rebellion Paintworks.

-

Zodiac Stretched fuel tank.

-

Modified Harley Davidson front mudguard - shortened and narrowed by me at Rebellion Paintworks.

-

West Coast Customs rear mudguard for 200 wheel modified to work with frame by Ralfy Customs.

-

Ultima 21” front and 19”x 200 rear wheel. Acid dipped to remove chrome then powder-coated in gloss black by LSN coatings. Spaced out and modified to work as needed in the custom frame. Spacers and engineering by Ralfy at Ralfy Customs.

-

6” over Ultima front end. All parts disassembled, acid dipped and then powder-coated by LSN in gloss black and rebuilt by myself and Ralfy.

-

All the paintwork was completed by myself through my business Rebellion Paintworks. Finished in an array of purples: Novak Purple pearlescent, Blueberry Pearlescent, Mystic Purple Metallic, Burple metal flake (ghosted pinstripes). Passion Pearl Purple finally guided in Real silver leaf (stripes) in-house at Rebellion Paintworks. Paints Manufactured and supplied by my friends at ‘Custom Paints’ in Sheffield.

Rich NCC Mercia

The Guzzi 850 Le Mans II

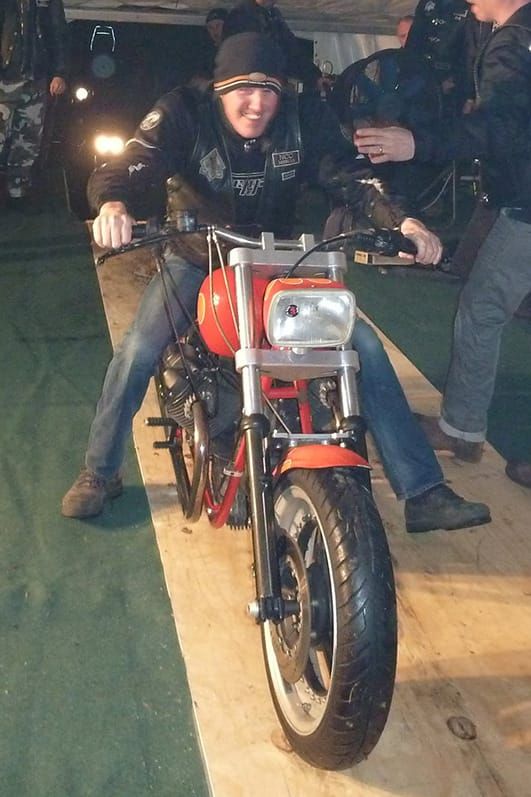

Ted NCC Honorary Member

I had been talking about possibly building an FJ 1200 based bike for a while then one-night fellow Club member and good friend Ian Kilner turned up. Nothing unusual about that, we only lived a couple hundred yards apart and often finished work and went home to the wrong house. We had a coffee and a smoke then he said "Oh by the way I've got an FJ motor in the van for you and should have some wheels, forks and a swing arm in a week or so. Don't worry about the money, pay me when you've got it." That was his way of saying don't just talk about it - do it. So that was that, I was going to do an FJ.

The frame was built by Ian in his early days at Revolution Motorcycles, Northampton in 1993. I think it was the third frame off his FJ jig and was a plain frame with no mounting lugs as I wanted to make all them myself and was dropped off on his way home from the shop.

I fabricated my own fancy mounting brackets for the engine and oil cooler and welded them to the frame then lowered the frame over the engine and bolted it in place. It sounds so simple when you write it down but working out where the mounting brackets needed to go to keep everything in line was a pig of a job with the engine balanced on blocks of wood in the frame, straight edges, spirit levels and cardboard cut outs all moving just as you thought it was spot on and I started regretting not having the plain brackets welded on while it was in the jig. With the engine in I fitted the forks and swing arm and finally got it up on its wheels. The bottom frame rails were as low to the ground as I wanted but I felt the seat rails were a bit too high and could have been lower. It sat there in my garage like that for some time and I kept looking at it but wasn't keen to carry on with the build until I was happy with the frame.

Eventually I came up with a plan. I worked out the smallest battery I could get away with then roughly mounted it as low down in the frame as I could and found there was three inches between the top of the battery and the top of the seat rails. There was plenty of room between the rocker cover and the top tube so I now knew what had to be done. Out with the angle grinder and cut the top tube and seat rails off, cut three inches out of the frame, refit the top tube and seat rails and weld it all back together with a bit of cutting and shutting here and there to make it all fit and some new gussets at the headstock. Then I ground down all the welds and set to work with some P38 and sandpaper as I wanted all the frame joints to flow seamlessly together.

When Ian saw what I had done he was not very impressed that I had cut up his handy work. He did agree that it did now sit lower, but didn't think it needed to and pointed out that everyone else was happy with his frames. I assured him I was happy with it; I was just happier with it now.

The rear mudguard is a wider version of the old sleek bob that Revo's used to have especially made for them. I cut out some struts and welded them to the inside of the sides to give it more strength. Made some mounts and welded them to the rear of the frame then cut slots in the mudguard so it slides over the mounts and bolts into place. The result is a mudguard that is strong enough to carry a pillion and a bolt on rack loaded with camping gear, but does not look it. The polished rear swingarm is stock FJ but I replaced the original spongy monoshock with a stiffer and slightly shorter one from Hagon. The rear wheel is a later modification and is a polished up wider one from an Exup, which to make fit I had to grind and cut down the cush drive lugs and rubbers and to keep everything true, have a bit of proper machining done which Dan of Dan Death Customs took care of for me.

The engine breaths in through a custom made airbox fabricated for me by Alders of Northampton who are sadly no more as he had a bad bike accident which left him with head injuries so severe, he couldn't carry on with his fabrication business. Dyna coils make it go bang and it breaths out via short four into two stainless pipes that I wanted tucked away under the engine for better clearance on twisty roads. They were made for me by Whiz from Peterborough who at the time was a club member. I made up some baffles for them to quieten things down a tad but more importantly to give the engine a bit of back pressure as I think Jap fours need this.

The tank is a quick bob from which I cut off and welded up the original filler then cut a big hole in the middle and fitted an aircraft style filler. Not being a fan of custom fuel taps I blanked off the port for one of these then welded and drilled a flat plate to the bottom of the tank and fitted a Kawasaki. tap with a proper filter and descent flow.

To light the way ahead I wanted something different than the off the shelf custom lights. I bought a cheap universal rectangular headlamp that was mounted in a black plastic shell and took it to Alders who made me a beautiful new shell and mounts out of stainless, the man really was a craftsman.

Steerage is taken care of with drag bars, held in place by one off stainless risers by Alders. At the time the only custom risers I could find were chromed steel and bolted together from the top, leaving holes in the top which filled with water. So, Alders made me some from stainless that bolt up from the bottom leaving the tops nice and clean. The risers sit on two inch wider than stock ally slab yokes with an ally fork brace to match and wheel spacers, all of which Revo's had made for me. The yokes clamp FJ forks and front wheel in place, polished of course. The front mudguard I had made and bolts up under the fork brace.

To stop me running into things, up front I've fitted blue dot callipers and master cylinder from an Exup with a clutch master cylinder to match from an XJR on the other end of the bars. The rear brake is stock FJ operated by a long agricultural looking brake pedal I made from an old torsion bar from a tailift, grinding it down to a taper, bending it to shape and welding the ends on it that I cut off an old pedal. It does occasionally draw comment, both good and bad, but I like it and with all that leverage it works well too.

To connect up all the electricky bits I made up my own wiring loom from scratch using reclaimed wire I had been collecting for the job and a Haynes wiring diagram. It took the best part of a week to do and to my relief, it all worked first time.

I painted everything that wasn't shiny with rattle cans in my garage but was never really happy with the blue green colour I had used so a few years ago I bought some more rattle cans and sprayed it in the blue black. At the same time, I changed the seat as I had originally done a dual seat that didn't look right so before repainting the rear mudguard, I made a single seat and bolt on pillion seat, sculpting the foam to the desired shape using an electric carving knife. The seat was then covered by whoever Sootys Customs got to do such things at the time.

The original build took way longer than it should have.... like years longer but still ended up being finished in a rush. I was on my way back from the NCC Herts custom show in July on my trusty old Kwak when I noticed a rumble from the bottom end every time, I rolled off the throttle. It got me home but there was no way I was going to ride it again until I had stripped the engine to see what ails it. I was booked on a ferry to go to the Chopper Club Netherlands Run at their clubhouse in Zaandam on the first weekend in August so had to get stuck in and get the FJ finished. I got it done just in time, Thursday night after work I was still faffing about with jets and needles until I had it running something like, then on Friday set off for Holland. Apart from having to retighten the exhaust header bolts half way there I had no problems.

It's a shame the same can't be said about the return journey. I ended up drinking far too much on the Sunday night and staggering back to my tent as it was getting light. Then having to get up again not long after to take the tent down, load the bike up and go round to the garage and fill up with petrol. And that is where things went horribly wrong. Halfway through filling up in my hungover state I realised it was the diesel pump I had stuck in my tank. With a ferry to catch there wasn’t time to muck about so I topped it up with petrol and hoped I could make it back to The Hoek. To make matters worse I was riding with a load of other members from various counties across the Diamond Empire who found it very funny...and still do.

With the carbs still full of neat petrol I knew it would start and get me to the end of the road, but what would happen when the diesel petrol mix found its way into my engine was my worry. We all set off and soon I was down on power with a load of smoke and a bit of spluttering, but as long as I kept the revs up when we slowed down it kept running and got me all the way back to the little square near the ferry terminal where we all stopped for coffee to await our boarding time.

The bike had done enough, but would do no more and would not start up when it was time to go to the ferry, but it’s not far and after a short bit of uphill its mostly downhill.... Holland doesn't have hills I hear you say, well try pushing a bike, then you'll realise it may not have hills but it does have inclines. Once on the ferry I strapped the bike down and found somewhere for a kip.

The bike didn't give me any more problems all the way back to England, but it wouldn’t do would it. Once we docked, I tried the bike but as expected it wouldn't start. I pushed it off the ferry and was directed to push it up the helter-skelter ramp thing they use which was definitely not going to happen. I had a word with one of the deckhands who opened a barrier for me to slip out the side. I pushed it up to and through passport control then through the customs check area, out of the terminal and down to the supermarket garage just down the road. I've made this journey loads of times and it always seems so quick, you leave the ferry terminal, quick blip of the throttle, over a roundabout and you're at the garage. That day it felt a hell of a lot further.

Opposite the garage was some waste ground so once there I took the tank off and emptied it over a clump of nettles that needed killing as they made the place look untidy. Refitted the tank and drained the carbs then pushed it into the garage and filled it up with lovely pure neat petrol. Not really wanting to start pulling plugs I tried starting it, one cylinder fired up straight away, then two more coughed into life and at last the fourth decided it didn't want to be left out and the bike sat there burbling away waiting to take me home.

Having made a few changes to the bike since then it is now just how I want it. In time it may need respraying or even an engine rebuild but I intend to keep riding it for as long as I can swing my leg over it. My only regret is that because I took so long to finish it, my old mate Ian Kilner who left this world far too soon never got to see it. I like to think that if he saw how it turned out he'd like it, and may even forgive me for hacking up his handy work.

Ted Northants.